- 17 October2024

- UX Design

- . Methods

- . Poka-Yoke

Improving UX Design with the Poka-Yoke Method

In the field of user experience (UX) design, ensuring smooth, intuitive, and error-free interactions is essential for user satisfaction. UX designers constantly seek innovative methods to optimize their creations. The Poka-Yoke method is a particularly effective approach borrowed from the Japanese manufacturing industry. In this article, we will explore how Poka-Yoke principles can be applied to UX design to create more robust and intuitive user experiences, examining concrete implementation examples.

History of Poka-Yoke

The concept of Poka-Yoke, a Japanese term that literally translates to "avoid error," has revolutionized production and quality methodologies in the industrial world. Born in the 1960s, this system was invented by engineer Shigeo Shingō, who was then working for Toyota, one of the pioneering companies in adopting innovative and efficient production methods. The word "Poka" means error, and "Yokeru" translates to avoid, perfectly illustrating the goal of this system: to prevent the occurrence of errors in manufacturing processes. In France, this mechanism is known as a mistake-proofing device.

Shigeo Shingō (1909 - 1990)

Initially, Poka-Yoke was known as "Baka-Yoke," where "Baka" means idiot, a term aimed at preventing "stupid" or simple inattentive errors. However, to avoid negative connotations and promote a culture of continuous improvement without stigmatization, the term was softened to Poka-Yoke.

The Poka-Yoke approach emphasizes detecting and preventing errors before they turn into costly defects, highlighting the importance of quality at every stage of the production process. Its implementation illustrates a philosophy where quality and efficiency are not just the concern of quality controllers but a constant commitment for all team members. Today, Poka-Yoke is widely used in many industries worldwide, attesting to its effectiveness and adaptability beyond the automotive sector.

Poka-Yoke in Our Daily Lives

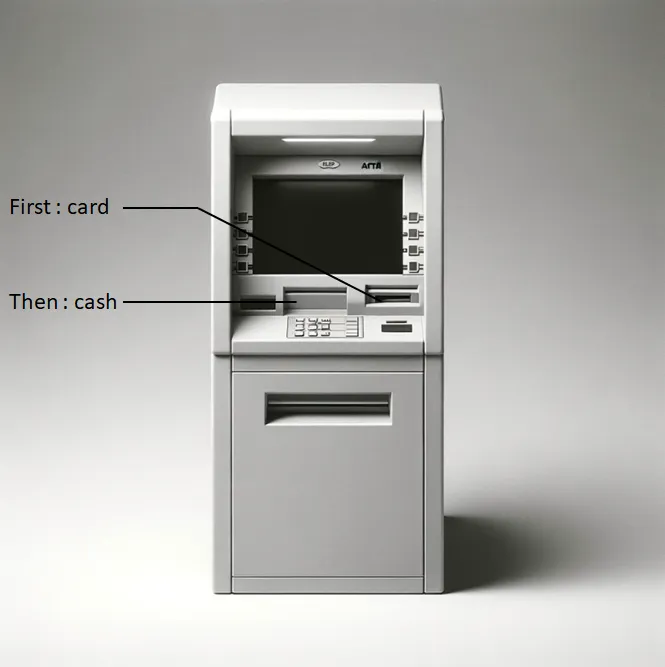

Poka-Yoke has entered our daily lives to make them easier. Each application of Poka-Yoke can be classified into one of these three categories: contact mistake-proofing, signal mistake-proofing, and chronological mistake-proofing. Here are some examples to illustrate Poka-Yoke in each category:

For example, SIM cards have a corner removed to prevent them from being inserted incorrectly into their slot.

For example, when your car's audible alert warns you of the proximity of a wall when reversing, an open door, or an unbuckled seatbelt.

For example, in an ATM, bills are only dispensed after the user has retrieved the withdrawal card.

Similarly, at a gas pump, fuel only flows if the card has been removed.

Application in UX Design

This methodology, key to the success of Toyota's production and omnipresent in our daily lives, also applies to UX design. Here are some examples you have probably seen without knowing they were Poka-Yoke:

Conclusion

In conclusion, the Poka-Yoke method proves to be a powerful tool not only for the industry but also for designing digital products, promoting a flawless and engaging user experience. Adopting this methodology can be a major asset for any design team looking to perfect their products and offer optimal interaction quality to their users.

Learn More

Shigeo Shingō (1909-1990) was a Japanese industrial engineer and management consultant, recognized for his major contributions to production management and continuous improvement. He is particularly famous for his work on the Toyota Production System (TPS) and for developing essential concepts such as Poka-Yoke and SMED (Single-Minute Exchange of Die). Here are some key points about his career and contributions:

Toyota Production System (TPS): Although often attributed to Taiichi Ohno, Shingō played a crucial role in developing and disseminating the TPS, which is the foundation of lean production methods. He helped Toyota reduce waste, improve quality, and increase production efficiency.

Poka-Yoke: Shingō invented this concept, which means "error-proofing" in Japanese. It involves simple devices or procedures that prevent human errors before they occur, thereby improving product quality and operational safety.

SMED (Single-Minute Exchange of Die): This method aims to reduce the time required to change tools or molds in production machines, allowing for greater flexibility and reduced downtime. The term "Single-Minute" means that tool changes should ideally take less than 10 minutes.

Works and Publications: Shingō wrote several influential books and articles on production and industrial management. Among his best-known works are "A Study of the Toyota Production System" and "Zero Quality Control: Source Inspection and the Poka-Yoke System".

Shigeo Shingō left a lasting legacy in the field of manufacturing and management, influencing generations of engineers and managers worldwide.

Poka-Yoke and Six Sigma are both quality management approaches, but they differ in focus and methodology. Poka-Yoke is a simple and practical method that focuses on preventing human errors by introducing mistake-proofing devices into processes. Six Sigma, on the other hand, is a more comprehensive approach that uses statistical techniques to identify and eliminate defects in production and service processes. Six Sigma aims to reduce variability and continuously improve quality, often through DMAIC (Define, Measure, Analyze, Improve, Control) projects.

Using Poka-Yoke in UX design offers several advantages, including reducing user errors, improving user satisfaction, and increasing process efficiency. By preventing incorrect actions, users can complete their tasks more smoothly and with less frustration, contributing to better application adoption.

Our experts will analyze your applications to identify improvement opportunities and provide you with a detailed document with concrete recommendations. Additionally, our team of developers is ready to implement these improvements to optimize your customers' user experience.

Ready to transform your UX Design?

The Syskeo team consists of passionate and experienced professionals. Our multidisciplinary team works in synergy to offer high-quality solutions based on the latest technological advancements and best industry practices.